| CLOSE [X] |

| CLOSE [X] |

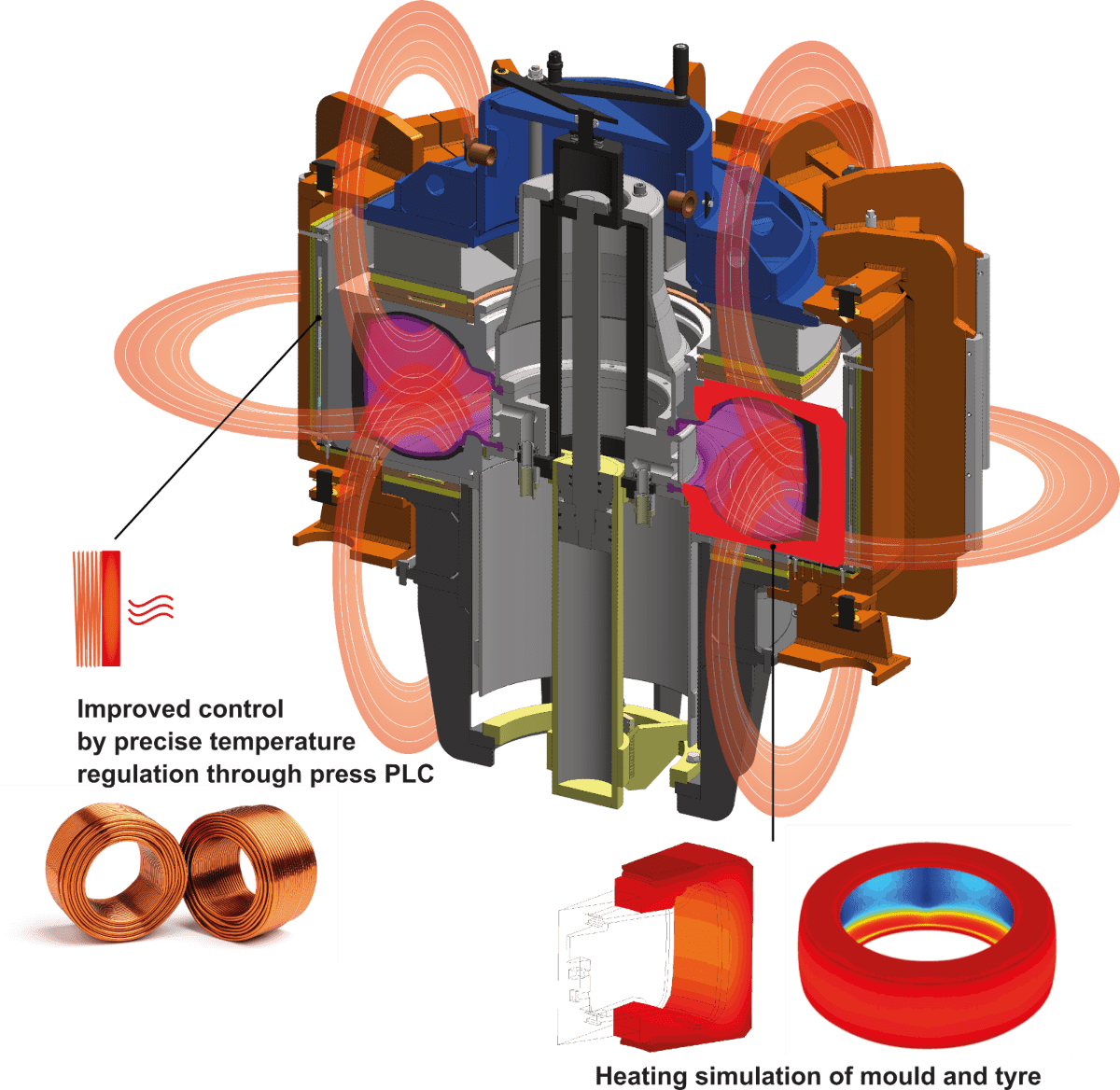

Induction heating is a highly efficient and fast method that uses a magnetic field to heat conductive materials, such as metals and semiconductors, without contact.

This method has become increasingly popular for industrial, medical, and domestic applications due to its many advantages over traditional heating techniques.

Induction heating is beneficial for highly precise or repetitive operations, where consistent heating and temperature control are critical for the quality and repeatability of the end product.

Compared to some of the classic heating techniques (resistance heating, flame heating, furnaces, etc.), induction heating has the following advantages:

· Reduced time -the target is heated directly, resulting in a reduction of both heating time and wasted heat. This method provides high power density and low or no thermal inertia.

· High efficiency - Temperatures can be reached quickly and easily as the ambient heat loss is significantly reduced.

· Improved control - precise regulation of the heating power can be achieved.

· Industrial automation option - induction heating allows improvement of both the productivity and the quality of the processes.

· Safety and cleanliness - there is no thermal or air pollution as the target is heated directly and no fuel substances are used.

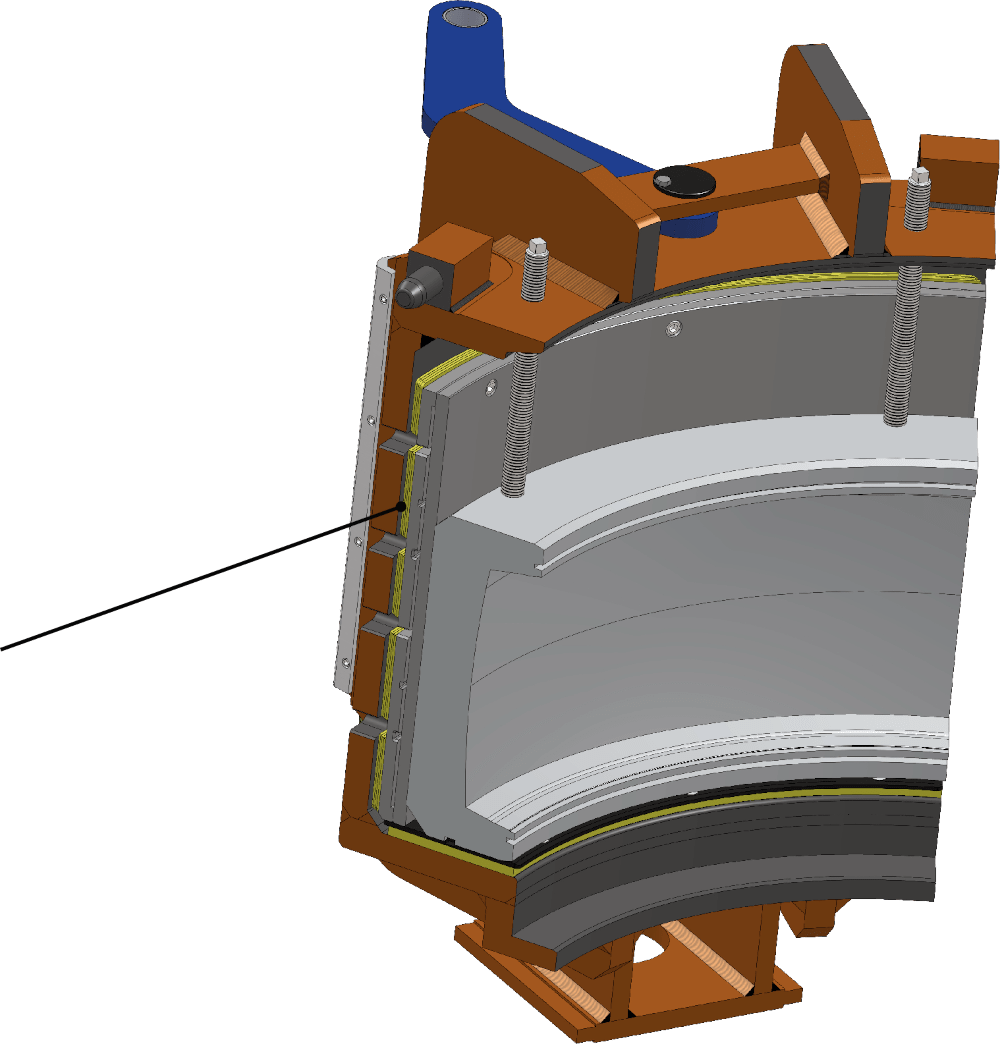

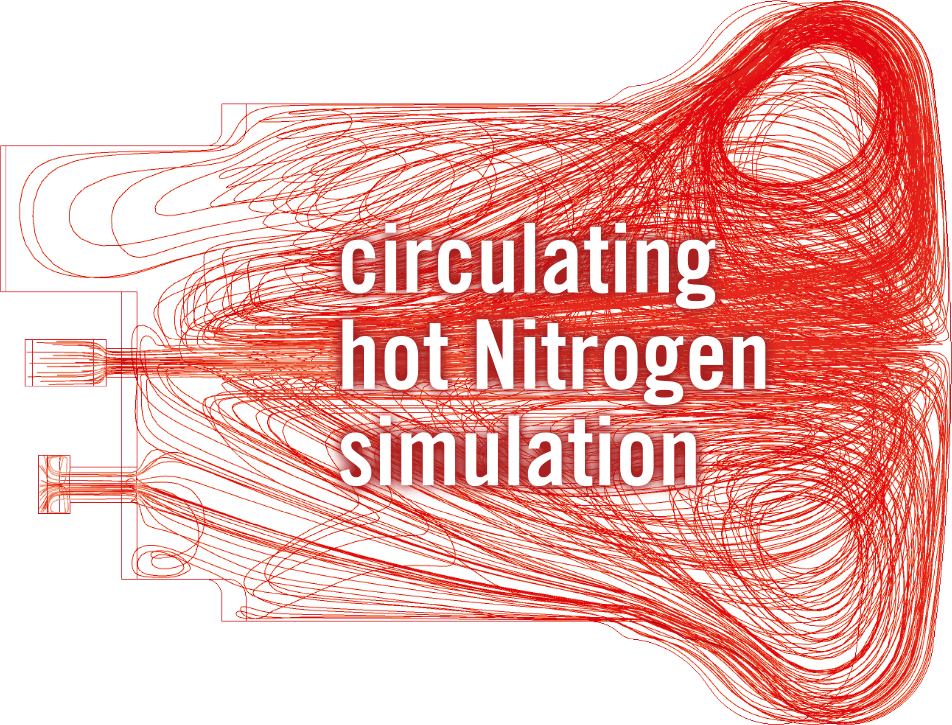

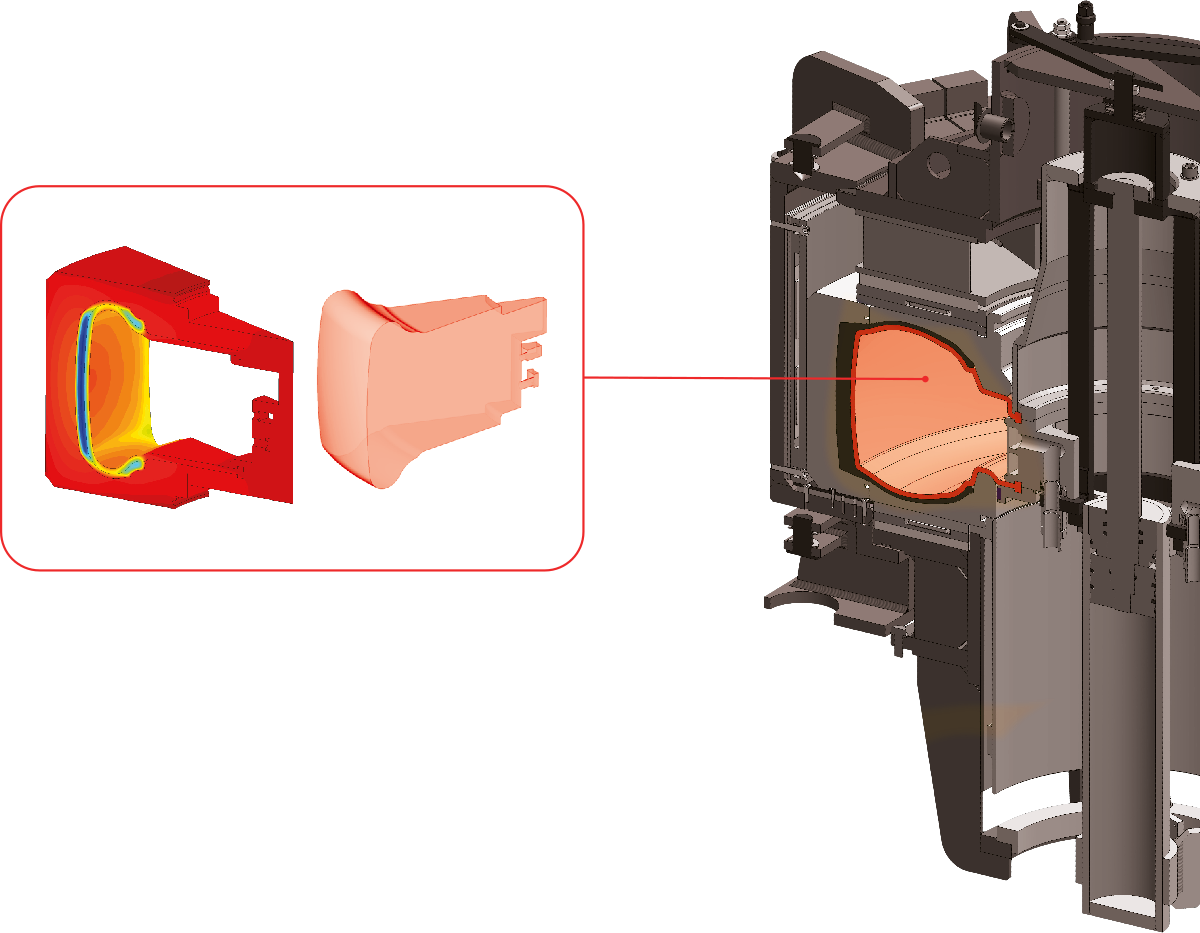

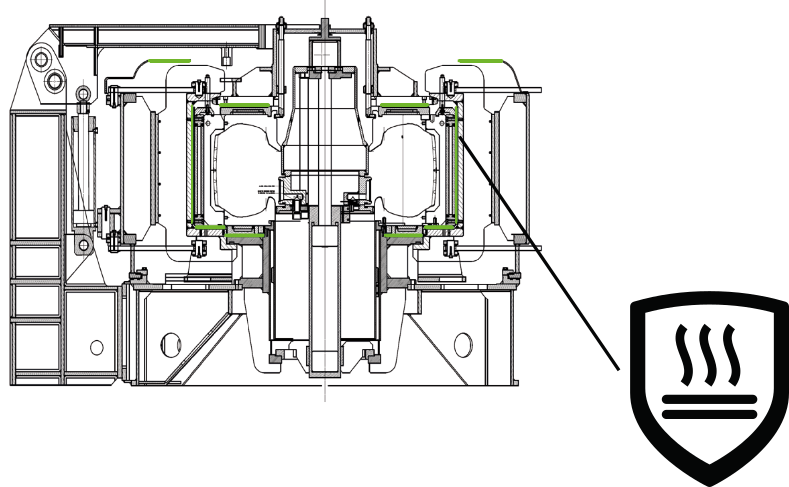

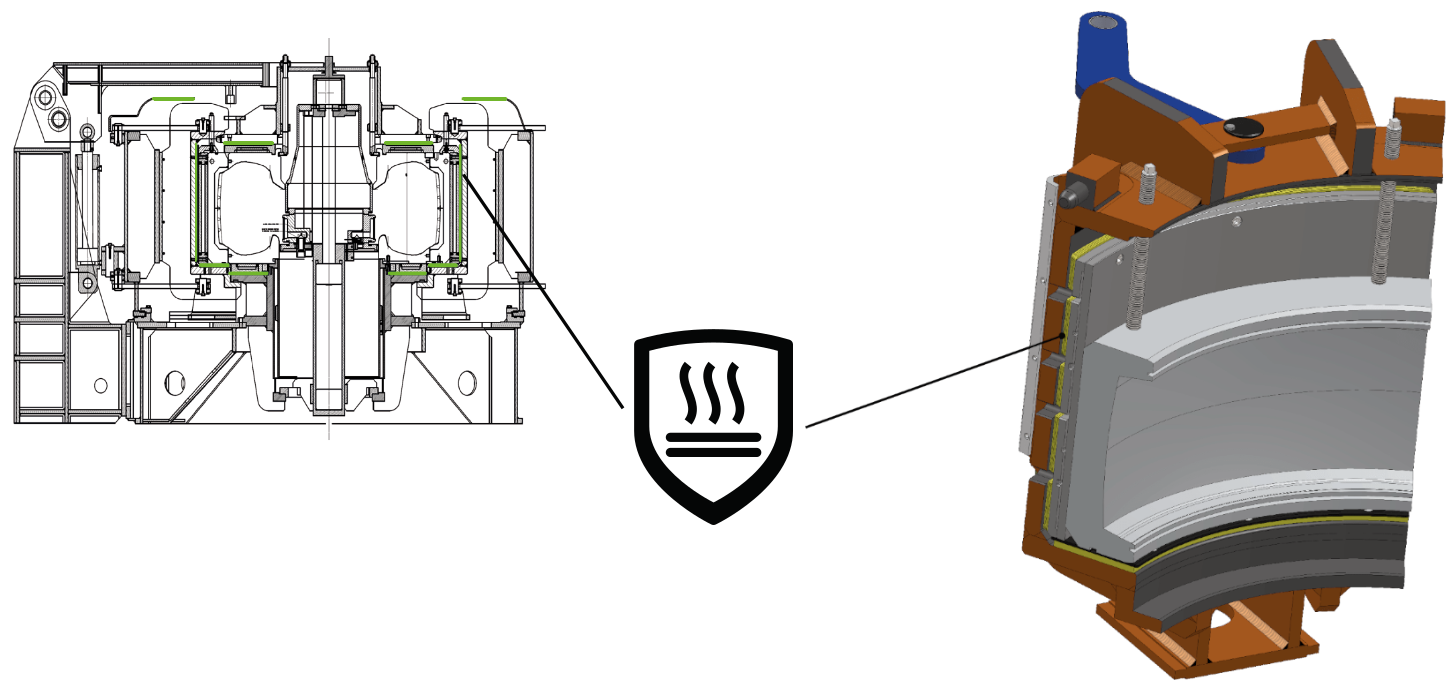

Integrated insulation solution for the vulcanization press without using coating equipment external to the machine itself, which does not block the heating of the machine body, and which often interferes with maintenance or possible dismantling of certain parts , but using specific materials mounted ALL INSIDE the press itself.

· Thickness: 10-15 mm

· Compression strength: 500 N/mm2

· Operating temperature: up to 200°C

· Thermal conductivity: 0,3 W/m°C

Differently from the most common way of insulating presses by COVERING EXTERNALLY the machine body with fiberglass or other material which does not avoid the external body of the press to become hot, our system blocks heat as much as possible in the cavity AVOIDING THE EXTERNAL STRUCTURE TO GET HO.T